Project SerPET

Recycling Plastic Bottles into High Performance Composites

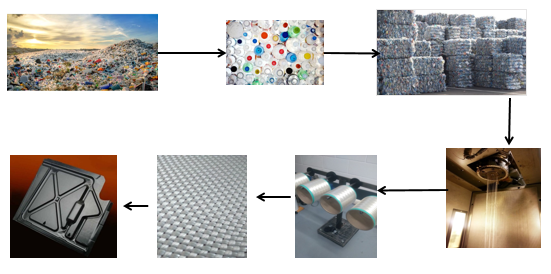

In 2017, the world used 20 million tonnes of polyethylene terephthalate (PET) in water and soft drinks bottles, equivalent to 3 kg for every man, woman and child on the planet! The bulk of post-consumer PET bottles go to landfill. Those collected for recycling become recycled PET (rPET) and it is economically viable to use this to manufacture fibres for relatively low value applications such as nappies and the filling for duvets. The Irish Composites Centre (IComp) at the University of Limerick has however developed the technology, patent pending, to convert rPET into high performance self-reinforcing polymer composite materials (SRP). Here, the reinforcing high tensile fibre is rPET and the matrix is rPET, making the composite parts themselves fully recyclable. These IComp SRPs are rapidly processable by low energy heating using microwave and radio frequency and potentially have high added-value applications in automotive, off-the-road vehicles, electronics, leisure goods, construction, etc. IComp has validated this technology on the research scale and is now proceeding to the development scale. To scale this up to production requires industrial-scale fibre spinning and weaving capabilities and IComp is looking for suitable industrial partners, preferably in Ireland, to exploit this technology to put UL and Ireland at the forefront of the fight against the highly topical plastic pollution of the planet.