University College Dublin and IComp were well represented at the 39th Adhesion Society Annual Meeting which took place in San Antonio, Texas. Prof Alojz Ivankovic and Dr Neal Murphy presented four papers on work related to the CCM-Bond project which addresses various challenges relating to composite-to-composite and composite-to-metal bonding.

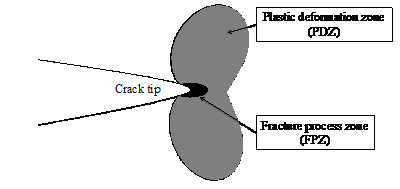

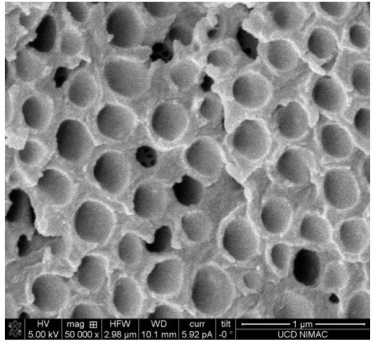

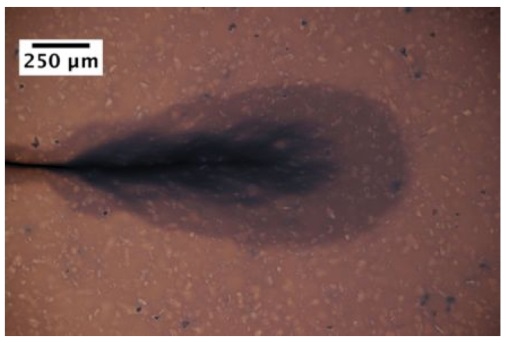

In the first paper, significant progress was made in understanding the dominant toughening mechanisms in a structural epoxy adhesive to which varying amounts of core-shell rubber nanoparticles had been added. It is well known that the significant increase in fracture toughness which is observed in these adhesives arises from energy dissipation in two distinct regions in the vicinity of the crack tip, as shown in Figure 1. These are the so-called “fracture process zone” (FPZ) associated with the intrinsic failure processes of the adhesive (in this case cavitation of the nano-particles and subsequent void growth), and the so-called “plastic deformation zone” (PDZ) further from the crack tip in which shear-dominant plasticity takes place, as shown in Figure 2.

Figure 1: Classical regions of energy dissipation at the tip of a crack.

Figure 2 (a) : SEM image of the fracture surface clearly showing the dominant fracture mechanism of void growth and coalescence following cavitation of the rubber nano-particles.

Figure 2 (b) : Right hand image shows the PDZ in bulk adhesive specimens using transmission optical microscopy.

It was clearly shown for the first time, using a combination of optical, scanning electron, and transmission electron microscopy that the size of the fully-developed FPZ was essentially constant in these materials, and variations in the observed fracture energy of both bulk specimens and adhesive joints of different bond gap thicknesses were due to variations in the size of the PDZ. The insight gained from this research will be of significant interest to both adhesive manufacturers and end users wishing to optimize the performance of their adhesive joints.

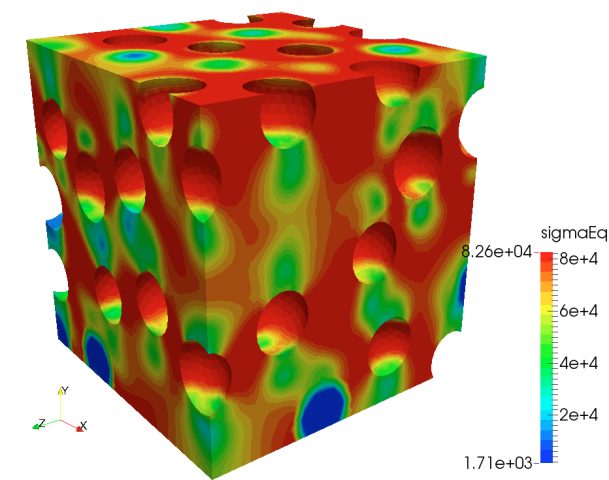

In the second paper, micro-mechanical modelling was employed to further investigate the nano-particle cavitation and subsequent deformation of the toughened epoxy adhesive. Here, a multi-scale modelling approach was used whereby the macroscopic states of stress and strain in the laboratory specimen are first calculated, and these results are used as the governing boundary conditions for a micro-scale model in which the details of the material microstructure are described in a so-called “Representative Volume Element” (RVE), as shown in Figure 3. In this way, the influence of the three-dimensional states of stress and strain (arising from different bond gap thicknesses, for example), can be accurately analyzed at both the macro and micro scales, providing further insight into the mechanical behaviour and toughening mechanisms of a given adhesive.

Figure 3: Stress distribution in a Representative Volume Element of a nano-toughened adhesive.

The third paper addressed the thorny issue of mixed-mode fracture, where the cracked component is subjected to a mixture of so-called opening and shear modes. This complicates the analysis considerably – of particular interest is the partitioning of the total fracture energy into its opening and shear components. In this paper it was shown that the partitioning depends strongly on the extent of the damage region ahead of the crack tip, and a novel procedure was presented to accurately estimate the energy partitioning for any material using a simple Excel-based software tool called SACA which is freely available from the UCD website (see http://adhesion.ucd.ie/caa/CAA_MixedMode.html).

The final paper discussed the mechanical and fracture characterisation of an elastomer-toughened cyanoacrylate adhesive (better known as “Superglue”). A comprehensive investigation of the bulk properties of the adhesive film and the fracture behaviour of associated composite-to-composite adhesive joints was carried out. Full details can be found in our recent paper in the International Journal of Adhesion & Adhesives (http://dx.doi.org/10.1016/j.ijadhadh.2016.03.001).

Prof Alojz Ivankovic enjoying some downtime at the Adhesion Society Meeting

Submitted by Neal Murphy